A Vortex Cavitation Reactor

We are on a mission to facilitate environmental sustainability through maximum resource utilization. To underpin this ambition we aspire to create a significant impact by enhancing process efficiencies in the manufacturing sector.

We leverage the power of vortex to greatly enhance productivity and resource utilization and aim to extract the utmost value from process assets.

Every manufacturing process dealing with

Flowing Streams

(single or multiphase) has a

Potential to improve its Operating

Efficiency

& to monetize those gains

as well as to reduce

generation of waste streams.

Effective use of resources and energy in the manufacturing sector demands not just gains in productivity but also valorization of waste streams via recover, recycle and reuse.

Loss of productivity in different processes

Reactive Processes

Conversion, Yield,

Selectivity

Non-uniform mixing,

Complex Multiphase

(L/L/G/S)

Residence Time, Energy Intensive, Footprint,

Safety

Purification Processes

Product Extraction

L-L, L-G extraction

Distillation, Mixing

.

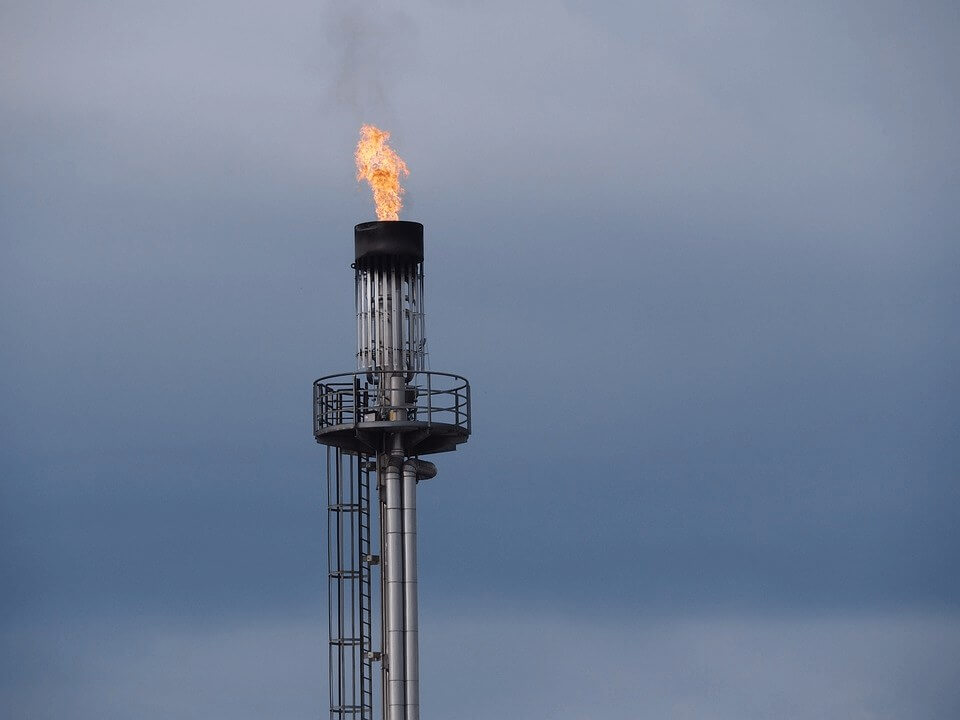

Waste Processes

AD efficiency, Emerging

pollutants, efficiency of

W2E, W2R, Footprint

Pre-Processing

Higher Processing Time,

Energy Intensive

Operations

High footprint

Separation Processes

Lower separation Efficiency

Evaporation,

Crystallization

Adsorption, Stripping etc.

Finishing Processes

Cleaning , Etching

Corrosive

Loss of productivity in different processes

Reactive Processes

Conversion, Yield,

Selectivity

Non-uniform mixing,

Complex Multiphase

(L/L/G/S)

Residence Time, Energy Intensive, Footprint,

Safety

Purification Processes

Product Extraction

L-L, L-G extraction

Distillation, Mixing

.

Waste Processes

AD efficiency, Emerging

pollutants, efficiency of

W2E, W2R, Footprint

Pre-Processing

Higher Processing Time,

Energy Intensive

Operations

High footprint

Separation Processes

Lower separation Efficiency

Evaporation,

Crystallization

Adsorption, Stripping etc.

Finishing Processes

Cleaning , Etching

Corrosive

Loss of productivity in different processes

Loss of productivity in different processes

Reactive Processes

Conversion, Yield,

Selectivity

Non-uniform mixing,

Complex Multiphase

(L/L/G/S)

Residence Time, Energy Intensive, Footprint,

Safety

Purification Processes

Product Extraction

L-L, L-G extraction

Distillation, Mixing

.

Waste Processes

AD efficiency, Emerging

pollutants, efficiency of

W2E, W2R, Footprint

Pre-Processing

Higher Processing Time,

Energy Intensive

Operations

High footprint

Separation Processes

Lower separation Efficiency

Evaporation,

Crystallization

Adsorption, Stripping etc.

Finishing Processes

Cleaning , Etching

Corrosive

Chemical Processes

Conversion | Waste | Extraction

Pharmaceuticals

OpEx | Refractory Pollutants

Textile Processes

Key Pollutants, Conversion, OpEx

Today’s Customers in manufacturing sector …

Barriers to innovation

Lack of knowledge on emerging technologies

Risk-averse attitude

Excessive time scales to adopt innovation

The manufacturing industry is under ever-increasing pressure to meet competing demands due to

Transition to

Circular Economy

Aging

infrastructure

Compliance

Constraints

Increasing

competition

The industry is actively searching for innovative solutions to achieve continuous improvement while addressing climate change and promoting overall sustainability.

VORTA is a key enabler to maximize the operational efficiency at large-scale.

VORTA does the most challenging work on maximizing the resource utilization to make it easier for our Customers to do the right things and help them realize the Circular Economy

With our climate friendly vortex technology, VORTA, we unlock the hidden gains in process streams.

For Illustration

For Illustration