VORTA for accelerating the reaction rate

Collapsing microbubbles from cavitation create intense local heating and pressure, which can generate high-energy conditions to overcome mass/heat transfer limitations to reduce the reaction time, boost conversion and yield of the desired chemical reaction.

Cavitation produced by VORTA can be used in various chemical reactions, including oxidation, reduction, hydrolysis, and polymerization.

VORTA for accelerating the reaction rate

Collapsing microbubbles from cavitation create intense local heating and pressure, which can generate high-energy conditions to overcome mass/heat transfer limitations to reduce the reaction time, boost conversion and yield of the desired chemical reaction.

Cavitation produced by VORTA can be used in various chemical reactions, including oxidation, reduction, hydrolysis, and polymerization.

Example 1

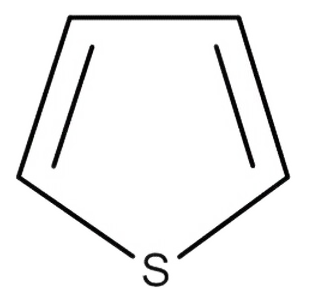

VORTA For Non-catalytic De-Sulphurization

VORTA demonstrated desulphurization of fuels using thiophene as a model compound with its initial concentration of 500 ppm up to 100% removal without use of catalyst at ambient conditions using in-situ oxidizing species generated from the mixed water. This research appeared in the scientific journal of Nature in year 2016 and can be viewed from this link

Example 2

VORTA For Biodiesel Production

Biodiesel is mostly produced from vegetable oil through a process of catalytic trans-esterification wherein oil reacts with alcohol to produce glycerin and biodiesel. The reaction breaks down the long-chain triglyceride molecules in the oil into smaller molecules of fatty acid methyl esters, main component of biodiesel.

VORTA with its controlled shear attributed to cavitating bubbles inside its vortex decreases the size of microbubbles in the dispersed phase increasing the interface area between the two immiscible phases. This results in to achieve more conversion and more yield at a much lesser energy.

Biodiesel - a renewable

fuel for diesel engines

“Are you exploring ….

To boost your existing figures on biodiesel conversion/yield ?

Transesterification from different vegetable oil ?