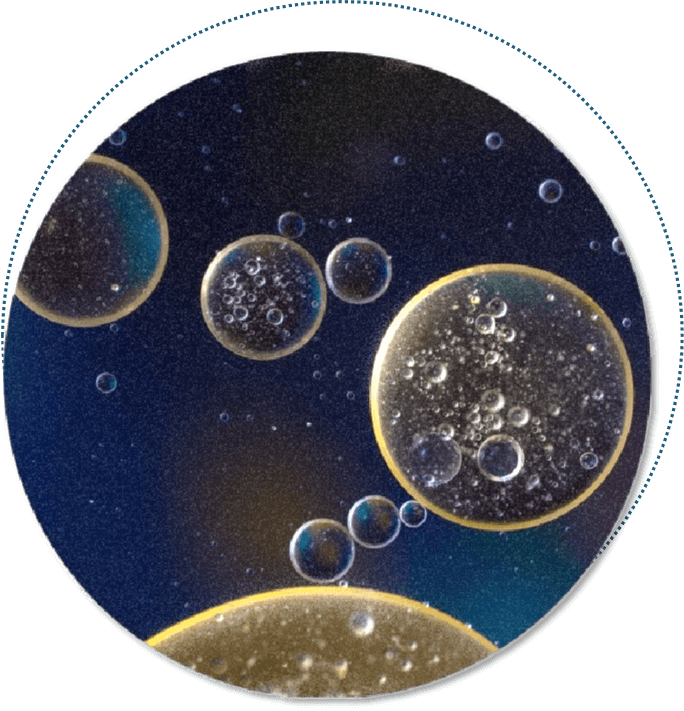

With VORTA we discovered an innovative way to modulate the flow to create shear and control the energy of imploding bubbles by containing them inside a vortex

Truly harnessing the two powerful forces in Nature

Conquering

Controlled

Cavitation

VORTA creates a field of controlled cavitation within the core of its inward vortex , which in turn makes intense forces available to induce physical/chemical changes in the flow-through stream.

VORTA can be seen as an in-line reactor that facilitates otherwise difficult and high-energy reactions by using a nominal amount of mechanical energy (1 kWh to treat 10 m3).

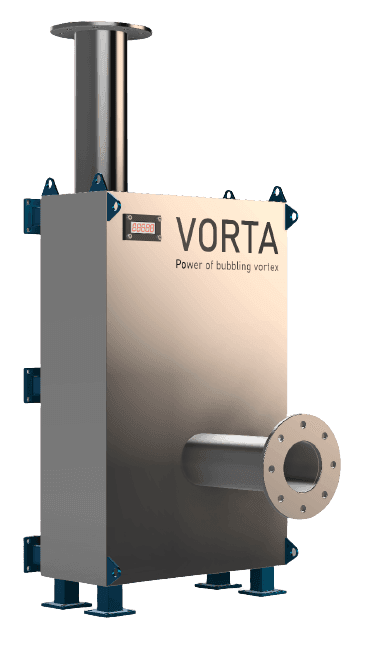

Design of VORTA

We are constantly exploring and validating new industrial processes that can exploit the promise of unique synergy of vortex flow, shear and cavitation

Compact footprint

Capacity | Length, L | Width, W | Height, H | 10 m3/hr 20 m3/hr 50 m3/hr | 0.5 m 0.7 m 0.75 m | 0.5 m 0.7 m 1.5 m | 0.75 m 1 m 1 m |

|---|

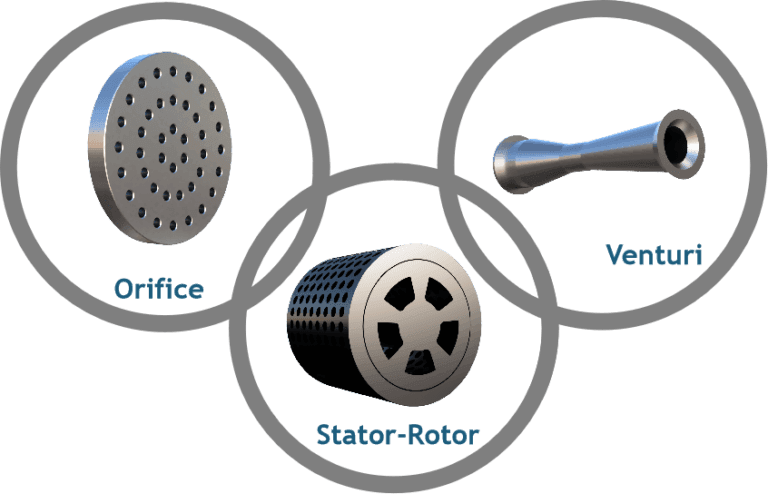

TRADITIONAL DEVICES TO PRODUCE

HYDRODYNAMIC

CAVITATION

Conventional venturi or orifice designs use linear flow conditions and a restriction of ~5 % total pipe area. Rotor-stators design involve moving parts

Hydrodynamic cavitation technology is not new however its implementation in large scale processing is very challenging due to following factors

One of the major challenges with cavitation reactors is scaling up from the laboratory to the industrial scale. The operating conditions that work well in the laboratory may not be effective in larger reactors.

Cavitation reactors require a significant amount of energy to operate. Therefore, improving the energy efficiency of cavitation reactors is essential for reducing operating costs

The bubbles generated during cavitation can coalesce and form larger bubbles, which can reduce the efficiency of the reactor. It is important to design the reactor to minimize bubble coalescence & maximize bubble collapse.

The high pressures and temperatures generated during cavitation can lead to erosion of the reactor material. This can limit the lifespan of the reactor and increase maintenance costs.

The intensity of cavitation can affect the performance of the reactor. Therefore, it is important to develop methods for controlling the intensity of cavitation to optimize reactor performance.

Problems

With conventional hydrodynamic Cavitation devices

Clogging Prone

Due to narrow restriction venturi/orifice are prone to clog with residual solids in the inlet slurry. Clogged device leads to a choked flow which removes the desired effects from cavitation

Less Life attributed to Erosion

Higher extent of erosion on the reactor walls due to collapsing cavities on the surface

Reduced Chemical Effect

Significant loss of collapsing cavities leads to relatively reduced amount of in-suit formed OH●

Higher OpEx

Due to linear flow conditions, the major cavitation effect occurs at a relatively higher pressure drop contributing to higher OpEx

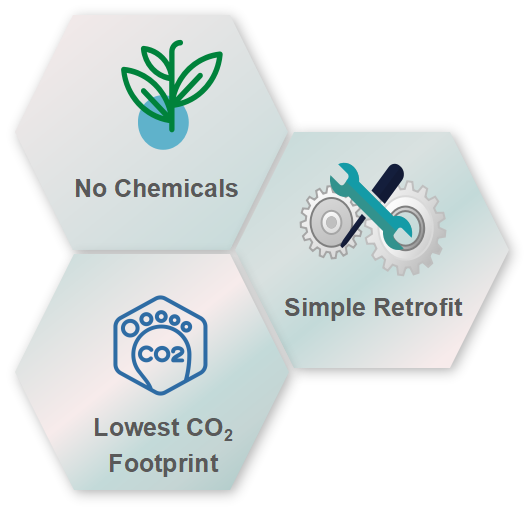

VORTA solves these problems by harnessing vortex flow

NO CLOGGING

There are no small holes in VORTA. This allows for treating slurries containing suspended solids. Consistency & more possibilities

ENHANCED CONTACT

Due to rotational flow there is an enhanced contact of multiphase components in the stream

More transformational efficiency

NO EROSION

Micro-bubbles collapse in the vortex core, which in turn is in the bulk of the liquid.

VORTA - More running life

ROBUST DESIGN

No Moving Parts. No

Choking flow conditions (bubble cloud)

VORTA - More running life

LOWER ENERGY

Conservation of Angular momentum allows for early inception of microbubble induced cavitation.

Lower pumping OpEx

RELIABLE & SCALABLE

Over 30+ commercial

Installations with capacity

Up to 20-50 m3/hr

Proven green-tech

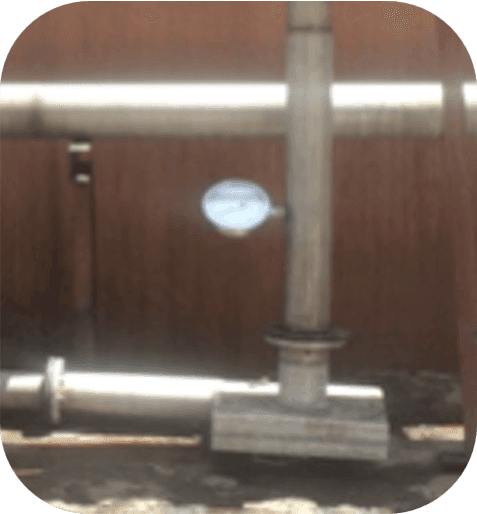

6 years and still counting

- Location : Pune, India

- Capacity : 10 m3/hr

- MOC : SS304

- Application : Pretreatment of feed to AD

VORTA’s longest installation is consistently

performing 24/7 without any erosion

since year 2017

- Location : Pune, India

- Capacity : 10 m3/hr

- MOC : SS304

- Application : Pretreatment of feed to AD

6 years and still counting

VORTA’s LONGEST

INSTALLATION is consistently

performing 24/7 without any

erosion SINCE 2017

6 years and still counting

- Location : Pune, India

- Capacity : 10 m3/hr

- MOC : SS304

- Application : Pretreatment of feed to AD

VORTA’s longest installation

is consistently performing

24/7 without any erosion

since year 2017

VORTA can be operated in batch mode as well as in continuous mode of operation

Decentralized Treatment

VORTA offers a possibility of treating Process Streams and Waste streams at their source before transferring them to equalization tank and allow for more effective treatment and local reuse. Distributed deployment of VORTA across various unit operations brings cascading benefits that add up to a significant boost in the cumulative efficiency of the operations

COMMERCIAL INSTALLATIONS OF VORTA

VORTA earned high standard of operational assurance

VORTA

sold in 13 countries

VORTA SOLD

in 13 Countries

What our Customers say?

VORTA was retrofitted in our plant in the year 2017 to pre-treat the feed to the biodigester in our plant. VORTA is performing consistently that resulted in an overall increase of 15% more biogas yield.

VORTA was commissioned for the purpose of biogas yield enhancement across the biodigester in our distillery. VORTA is in operation since April 2018 and is performing consistently to our fullest satisfaction.

VORTA reactor rated at 20 m3/hr was installed in our distillery in April 2020 and it consistently demonstrated an increased enhancement of 17+% in biogas yield from our Anaerobic Digestor. This resulted in 7 tones per day of bagasse requirement at the boilers.

We commissioned VORTA for the purpose of effluent treatment for our waste water treatment plant. VORTA is in operation since April 2017 and is performing to our fullest satisfaction.

VORTA Technology was installed in our plant in March 2019 and since that it has helped to consistently enhance the biogas yield from our spent wash digesters by more than 10%

Awards and Recognition

WITH SUPPORT FROM OUR TRUSTED PARTNERS