VORTA for Valorization of Dairy Sludge

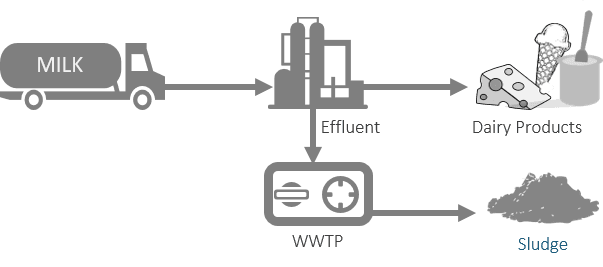

Worldwide dairy processing plants produce high volumes of dairy processing sludge (DPS).

DPS refers to the residual material generated from effluent treatment plant attached to the plant producing various dairy products such as cheese, yoghurt, ice-cream.

The Significant Challenges in disposal

of dairy sludge

Cost of transporting sludge is expensive

EPA is limiting the disposal of sludge

Sludge is fundamentally bad for the environment

Can we valorize the sludge

at the premises ?

The European dairy processing industry processed about 155 billion liters of domestic milk in 2022, about 50% more than the USA. It is estimated that dairy food processing wastewater treatment can generate up to 20 kg DPS per m3 of milk processed which resulted in 3.1 million tons of DPS (wet weight) across the EU in 2022!

Such large volume of sludge produced every year can be typically identified as sludge from Dissolved Air Floatation (DAF sludge) and the Brown sludge. These waste streams comprise significant carbon content and can be in principle valorized by using as substrate in anaerobic digestion. However, these sludges are not easily digestible.

VORTA offers suitable pre-treatment and significantly enhances biomethane yield and therefore valorization of dairy industry sludges